In the rapidly evolving field of biomedicine, the development of artificial skin and tissue substitutes is a game-changer. At the forefront of this innovation is the Pak-Austria Fachhochschule: Institute of Applied Sciences and Technology (PAF-IAST), located in Haripur, Khyber Pakhtunkhwa. Through a pioneering research initiative funded by the Khyber Pakhtunkhwa Science Agenda under the R&D Consortia Program of the Directorate General of Science & Technology (DoST), PAF-IAST is pushing the boundaries of 3D bioprinting technology to create advanced materials for medical applications. The project, titled Development of Artificial Skin and Tissue Substitutes Based on 3D Bioprinted Advanced Materials, is set to transform healthcare by addressing critical challenges in tissue engineering and regenerative medicine.

This blog post dives deep into the details of this innovative project, exploring its objectives, methodologies, potential applications, and the broader implications for the biomedical industry. Whether you’re a tech enthusiast, a medical professional, or simply curious about cutting-edge science, this guide will provide a comprehensive overview of how 3D bioprinting is reshaping the future of healthcare.

What is 3D Bioprinting?

Understanding the Technology

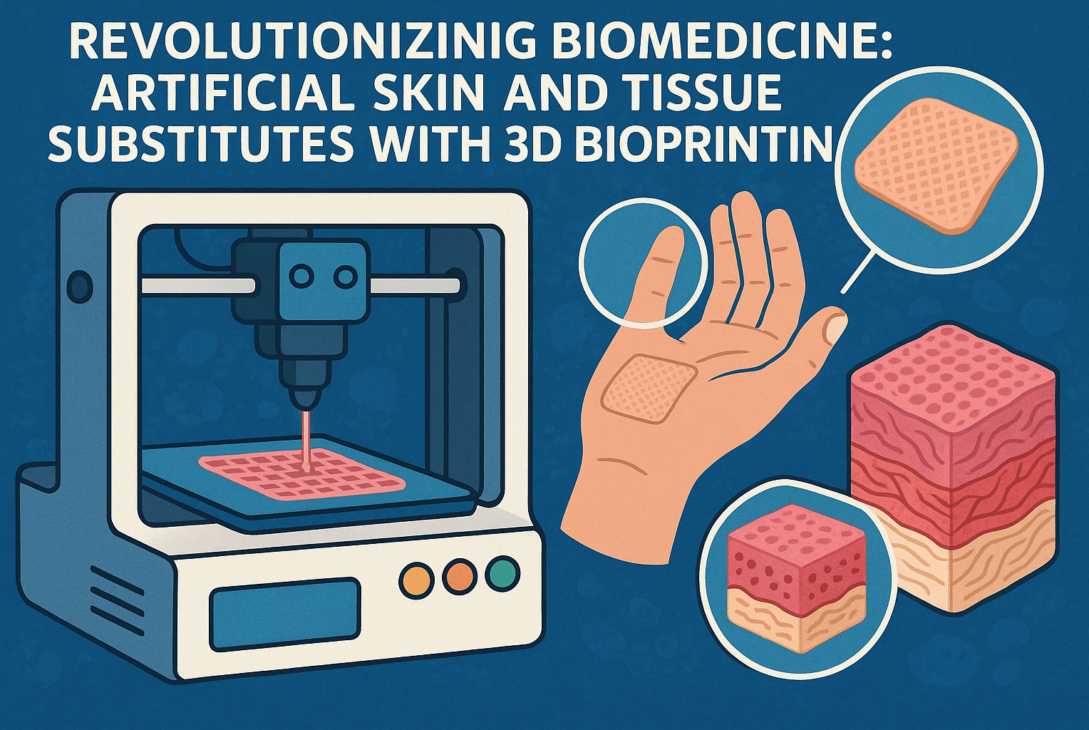

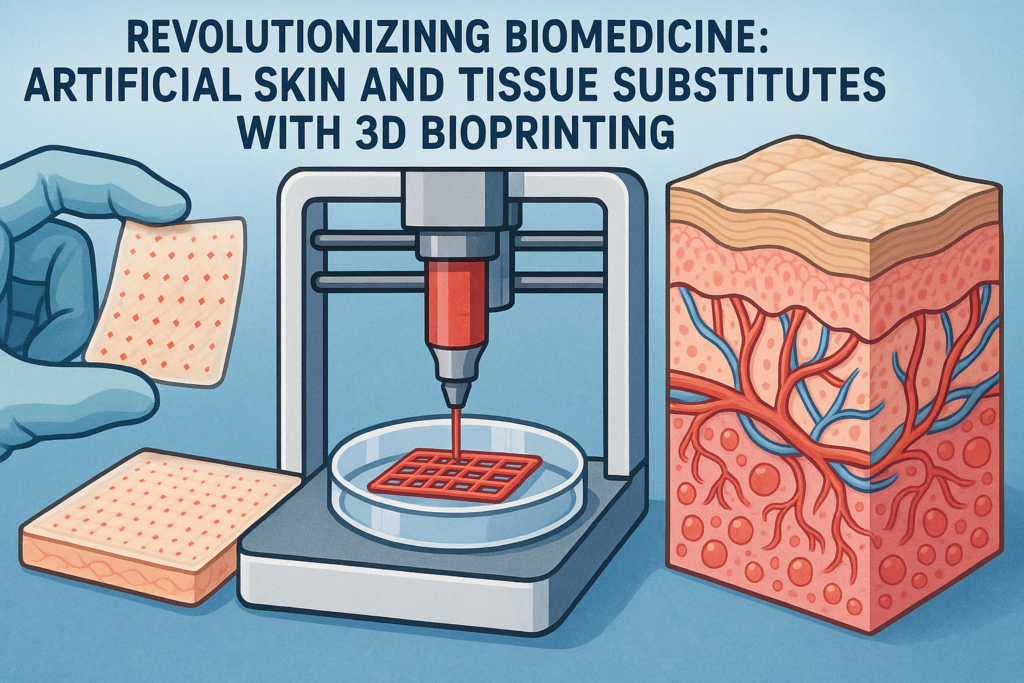

3D bioprinting is an advanced manufacturing technique that uses 3D printing technology to create complex biological structures, such as tissues and organs, layer by layer. Unlike traditional 3D printing, which works with materials like plastic or metal, bioprinting utilizes bioinks—specialized materials composed of living cells, biomaterials, and growth factors. These bioinks are precisely deposited to form functional tissue structures that mimic the natural properties of human tissues.

How 3D Bioprinting Works

The process of 3D bioprinting involves several key steps:

- Design Phase: Researchers create a digital model of the desired tissue or organ using specialized software.

- Bioink Preparation: A bioink is formulated, typically containing living cells (such as stem cells) and biocompatible materials like hydrogels.

- Printing Process: The bioink is loaded into a 3D bioprinter, which deposits the material layer by layer to form the tissue structure.

- Maturation: The printed structure is incubated in a controlled environment to allow cells to grow, differentiate, and form functional tissue.

This technology has immense potential in tissue engineering, enabling the creation of artificial skin, cartilage, and even complex organs for medical applications.

PAF-IAST’s Biomedical Research Initiative

Project Overview

The Development of Artificial Skin and Tissue Substitutes Based on 3D Bioprinted Advanced Materials project at PAF-IAST is a flagship initiative under the Khyber Pakhtunkhwa Science Agenda. This program, supported by the Directorate General of Science & Technology (DoST), aims to foster cutting-edge research and development in critical scientific fields. The project focuses on leveraging 3D bioprinting to create artificial skin and tissue substitutes that can be used in medical treatments, such as burn care, wound healing, and reconstructive surgeries.

Objectives of the Project

The PAF-IAST research team has outlined several key objectives:

- Develop Advanced Bioinks: Create bioinks with enhanced biocompatibility and mechanical properties to mimic natural human skin and tissues.

- Optimize 3D Bioprinting Techniques: Refine bioprinting processes to achieve high precision and scalability for clinical applications.

- Address Medical Challenges: Provide solutions for patients with severe burns, chronic wounds, or tissue loss due to injury or disease.

- Promote Regenerative Medicine: Contribute to the global advancement of regenerative medicine by developing tissues that can integrate seamlessly with the human body.

Why Artificial Skin and Tissue Substitutes Matter

The development of artificial skin and tissue substitutes addresses several pressing challenges in healthcare:

- Burn Treatment: Burn victims often require skin grafts, which are limited by donor availability and risk of rejection. Artificial skin can provide a readily available alternative.

- Chronic Wounds: Conditions like diabetic ulcers require advanced wound-healing solutions, which bioprinted tissues can offer.

- Reconstructive Surgery: Tissue substitutes can aid in reconstructive procedures, improving outcomes for patients with severe injuries or congenital deformities.

- Drug Testing and Research: Bioprinted tissues can serve as models for testing new drugs, reducing reliance on animal testing and accelerating medical research.

The Role of Advanced Materials in 3D Bioprinting

What Are Advanced Materials?

In the context of 3D bioprinting, advanced materials refer to biocompatible substances that can support cell growth and tissue formation. These materials must possess specific properties, such as flexibility, strength, and the ability to degrade safely in the body. Common materials used in bioprinting include:

- Hydrogels: Gel-like substances that provide a supportive environment for cells.

- Collagen: A natural protein found in human tissues, ideal for mimicking skin and connective tissue.

- Synthetic Polymers: Engineered materials designed to enhance the durability and functionality of bioprinted tissues.

Innovations at PAF-IAST

The PAF-IAST research team is focusing on developing novel bioinks that combine natural and synthetic materials to create tissues with improved functionality. These bioinks are designed to:

- Support cell viability and proliferation.

- Mimic the mechanical properties of natural skin, such as elasticity and tensile strength.

- Enable precise control during the bioprinting process for complex tissue structures.

By optimizing these materials, the project aims to create artificial skin that closely resembles human skin in both structure and function, paving the way for clinical applications.

The Impact of the Khyber Pakhtunkhwa Science Agenda

Empowering Regional Innovation

The Khyber Pakhtunkhwa Science Agenda, spearheaded by the Directorate General of Science & Technology (DoST), is a visionary initiative aimed at fostering scientific research and innovation in the region. By funding projects like the one at PAF-IAST, the agenda is positioning Khyber Pakhtunkhwa as a hub for cutting-edge research in biomedicine and tissue engineering.

Collaboration and Knowledge Sharing

The R&D Consortia Program encourages collaboration between academic institutions, industry partners, and government bodies. This collaborative approach ensures that research outcomes are practical, scalable, and aligned with real-world needs. PAF-IAST’s project is a prime example of how regional initiatives can contribute to global advancements in healthcare.

Challenges and Future Directions

Overcoming Technical Hurdles

While 3D bioprinting holds immense promise, it also faces several challenges:

- Vascularization: Creating tissues with functional blood vessels to ensure long-term cell survival.

- Scalability: Producing large-scale tissues for clinical use while maintaining precision and quality.

- Regulatory Approval: Ensuring bioprinted tissues meet stringent safety and efficacy standards for medical use.

The PAF-IAST team is actively addressing these challenges through rigorous research and testing, with the goal of bringing their innovations to clinical settings.

The Future of 3D Bioprinting

The success of this project could have far-reaching implications for biomedicine:

- Personalized Medicine: Bioprinted tissues tailored to individual patients could reduce the risk of rejection and improve outcomes.

- Organ Transplantation: In the long term, 3D bioprinting could lead to the development of fully functional organs, addressing the global shortage of donor organs.

- Global Impact: By advancing tissue engineering, PAF-IAST’s work could contribute to breakthroughs in healthcare worldwide.

Why This Matters for Pakistan and Beyond

The PAF-IAST project is not just a scientific endeavor; it’s a testament to Pakistan’s growing role in global innovation. By investing in 3D bioprinting and biomedical research, the country is positioning itself as a leader in the field. The project also highlights the importance of regional initiatives like the Khyber Pakhtunkhwa Science Agenda in driving technological progress.

For patients, the development of artificial skin and tissue substitutes could mean faster recovery times, reduced healthcare costs, and improved quality of life. For researchers and medical professionals, it opens new avenues for collaboration and discovery.

Call to Action

Excited about the future of 3D bioprinting and artificial skin development? Stay updated on the latest advancements in biomedicine by subscribing to our newsletter! Want to dive deeper? Check out our related article on The Future of Regenerative Medicine or share your thoughts in the comments below. Let’s spark a conversation about the transformative potential of tissue engineering!